MODULAR CRAFT

INITIATING THE GARMENT ECONOMY

Permet is building a regenerative garment production ecosystem, driven by ownership and aligned incentives for participants across the entire garment supply chain. This primer describes the mechanisms and resulting implications of the first experiment in this ecosystem: a garment collection co-owned by the people who contributed to its creation. In this new ecosystem: Culture is composable. Fashion enters the world of open-source collaboration – enabled by immutable creative provenance. Atomic units of creative work now act as “legos” that be remixed and built upon.

Creators and producers are in control. Ecosystem participants have unprecedented access to profit redistribution and new revenue streams – enabled by verifiable ownership of their work. Greenwashing is impossible and labor violations can’t be obscured. The garment supply chain is transparent with production process data openly available and auditable. Finally, modern garment production can actualize its fullest potential – with the means of production owned by its participants.

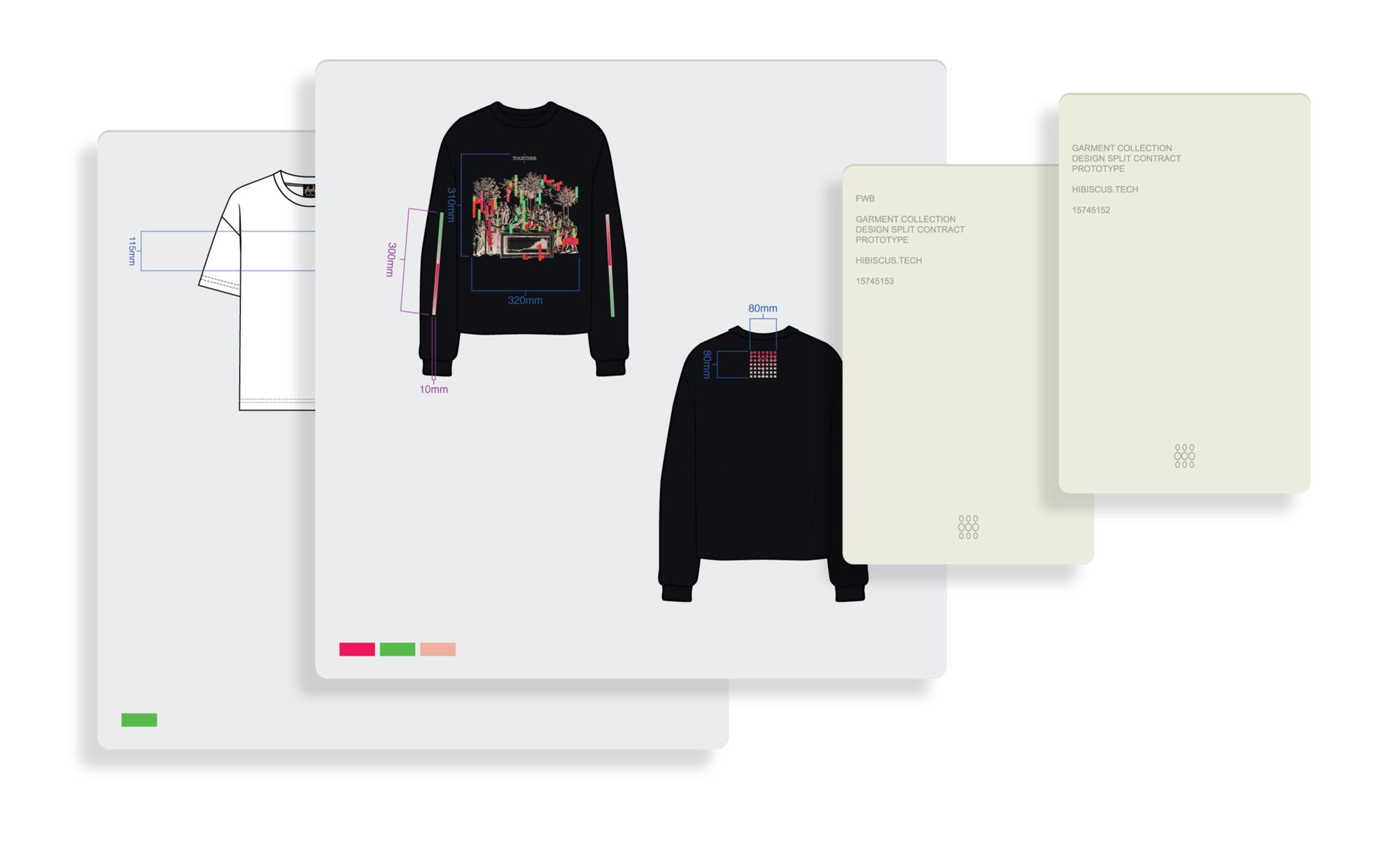

We’ve created a mutable split contract as a mechanism to build a clothing collection co-owned by its producers. The profits were redistributed using the Ethereum blockchain to record creators’ contributions to the garments – and subsequently route profits to their encrypted wallets. Access to profit distribution was encoded into NFTs that represent the creators’ designs, artworks and production files.

By creating an environment where creators can express their ideas freely, without fear of appropriation, we set the stage for permissionless cultural experimentation and development. One of the largest cultural mediums, fashion, exists in how humans across the globe dress themselves each day. And this culture does not exist in a vacuum. It is living and breathing – constantly in flux and building upon itself. Creating the rails to open-source fashion – a “lego set” of garment building blocks by creatives and producers, for creatives and producers – enables a Cambrian explosion of development in this $2 trillion industry. But perhaps even more importantly, these rails also lay the foundation to eliminate the labor exploitation and environmental impacts that currently exist within fashion.

With new modes of revenue generation, and transparency in the supply chain we are actualizing the tools with which to reshape the garment production industry in favor of the people. This is the only first step in a journey to build a regenarative garment production ecosystem.

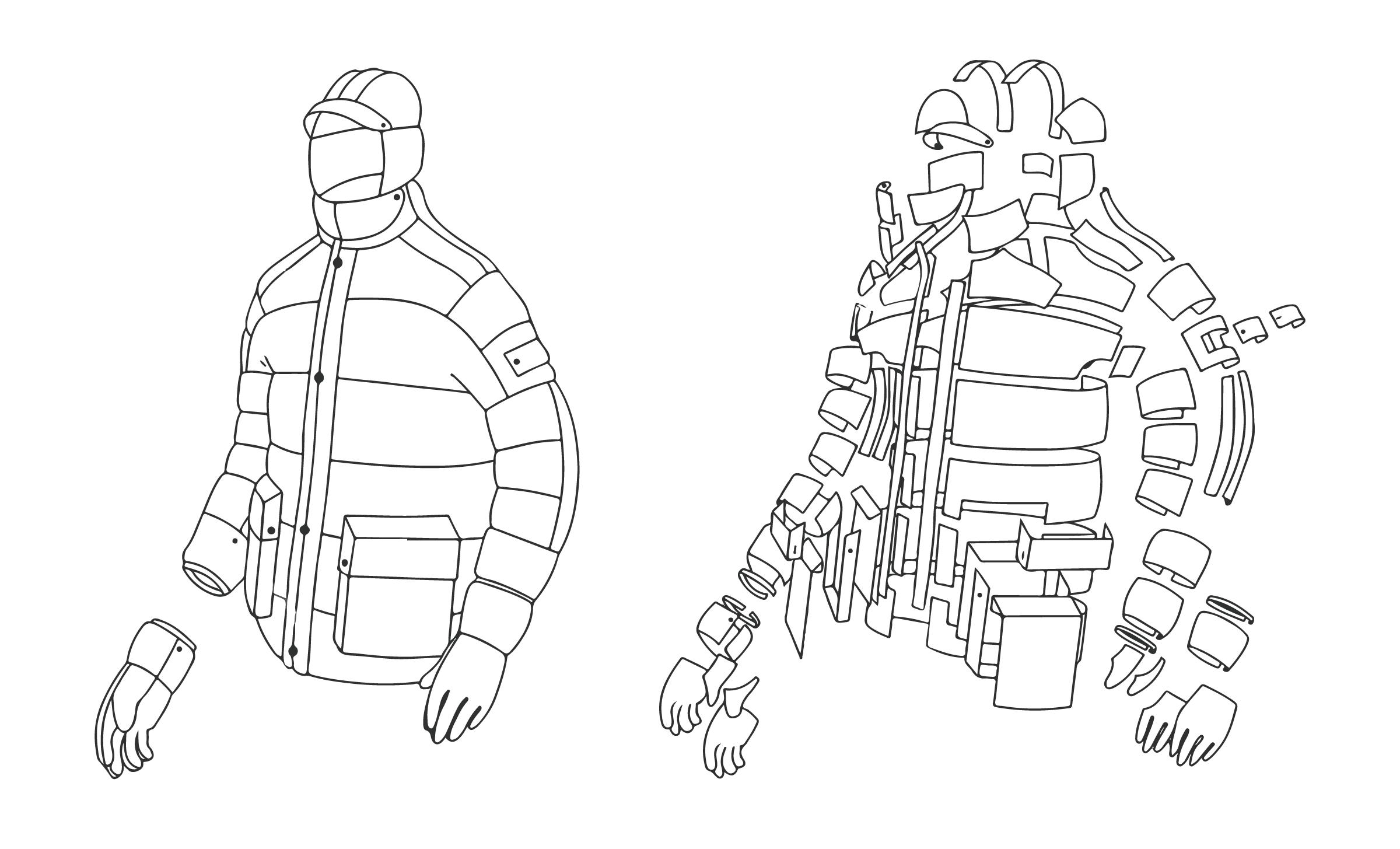

Every pattern, shape, and form can already be built upon and remixed. This is how creative innovation works – and happens every day in industry. Permet is building tools that allow these designs and artworks to become combinatorial in an accessible, provable manner. These atomic units of culture can now act like building blocks, enabling the creation of new designs while allowing each unit to remain independent so other creators can build on them too.

Design NFTs

Design NFTs are owned by the contributors to a project – but are available for anyone to build upon permissionlessly and/or freely trade on a decentralized market. Garment production processes and other contributions are documented by project participants – who mint these works as Design NFTs that record ownership and are programmable. This enables creative provenance and profit redistribution. Fashion photographers, stylists, art directors, writers, etc. can partake in redistribution. The eventual Permet platform can serve as a basis for open-source and collaborative creation – a “Github for creative production”.

Creative provenance is secured by verifiable attribution that Design NFTs enable. Even though each Design NFT might be right-click saved by malicious actors, the eventual plagiarized garment produced will not have the chain of provenance that can guarantee authenticity. We encourage new, regenerative modes of collaboration – secured by creative provenance. Designers, collectives, and communities can now collaborate openly – unlocking infinite ways to grow new headless brands. In this way – Permet embodies the spirit of early streetwear, a movement that encourages creators to use whatever means available to them to create impactful designs. Opening up this store of raw materials for creatives to build upon is our vision for the future of multiplayer product creation.

Enabling New Revenue Streams for Craftsmanship

While our split contract doesn’t currently include functionality for capturing and open-sourcing the data resulting from our production process – we are working on it. Despite this, ethical production is in our DNA. The goods were produced using Ecocycle® yarn: 50% recycled, 50% BCI (Better Cotton Initiative), 100% cotton yarn from premium Spanish mill Belda Lloréns. Ecocycle® yarn is produced at the Belda Lloréns facility in Alicante, Spain, which is 75% powered by solar energy, and comes with Oeko-Tex Standard 100 and Global Recycled Standard certificates.

The yarn’s 50% recycled component is sourced from Belda Lloréns’ recycling partners, who mechanically recycle cotton fabrics that have been sourced in Europe and the United States. Every pound of Ecocycle® yarn saves 5.46 square miles of land cultivation, 2,024 gallons of water, 14.90 kWh of electricity and 7.85 lbs of CO2 compared to conventionally grown cotton. The factory we used is utilizing a closed-loop system in partnership with Belda Lloréns. Every month all of the knitting and garment production waste, that would otherwise end up in a landfill, is shipped back to Belda Lloréns to be broken down into Ecocycle® yarn. As the United States is a net import country, these ships will be going back to Spain regardless, so there is no additional carbon footprint created.

Building a Network of Micro-Factories and At-Home Producers

Onboarding the full supply chain onto these blockchain-enabled mechanisms won’t happen overnight, but we think it should be bottoms up – via a decentralized network of producers. And we are actively working on making this this part of garment production open-source and verifiable. Permet is currently setting up our first distributed production network of micro-factories and at-home producers in Toronto, Canada.

The Future of Ethical Production

The real benefit of using blockchain for fashion is that it enables the beginning of a transparent and verifiable design and production landscape. In addition to a participant-owned system of producing clothes – we are working toward consensus-driven blockchain technology to verify that products are being made ethically & sustainably. We are focused on ushering in a production system supported by human-rights and environmental-impact oracles to verifiably eliminate the practices that fast fashion players and other industry monoliths have proliferated.

Building this new system can force traditional apparel brands into an “arms race” towards ethical production by driving adoption of a new industry standard of cryptographic verification in the supply chain. This would make greenwashing and obscuring labor practices impossible. Corporations who currently have a stranglehold on fashion would be forced to adopt ethical supply chain operations, verified by oracles, or admit – by omission – to committing human rights or environmental violations.

THE MEANS OF PRODUCTION

BEHIND THE PERMET TECHNOLOGY STACK

The Permet team has experience designing and producing garments for traditional brands as well as product and engineering experience from organizations like Gitcoin, Dapper Labs, Unstoppable Domains, VMWare, and Wikipedia. By implementing these new methods in our own Permet collections and in direct collaboration with other brands and organizations – we can dogfood (test our own products) and iterate on our processes and tools before they are ready for general protocol release. As a result, we are first experimenting with these new garment production systems in-house.

By implementing these new methods in our own Permet collections and in direct collaboration with other brands and organizations – we can dogfood (test our own products) and iterate on our processes and tools before they are ready for general protocol release. As a result, we are first experimenting with these new garment production systems in-house. However – the code is open-source and we encourage communities to reuse, fork, and remix it for their own immediate needs.

This collection includes 2 key components of the Permet technology stack:

- Design NFTs – and Garment NFTs, more generally

- Split Contract

This means that designers, pattern makers, product developers, sewers, machinists, 3D artists, photographers, or anyone else who took part in a project’s creation and success can be acknowledged for their work. This is important because, previously, work couldn’t be made freely available as it would simply be copied and not attributed to its creator. And even if proper attribution was the intention – the ability to assign and acknowledge provenance in an accessible way didn’t really exist. The introduction of Design NFTs flips the entire dynamic regarding reuse of ideas in the fashion industry – from discouraged and covert to beneficial and encouraged.

Now, creators will actively want their work to be adopted as they can take part in projects permissionlessly and still get a fair share of the value created. Each Design NFT acts as the key to access profit created from the use of the work – enabling uncapped royalties based on each participant’s participation in a project.